Dr. Matthew Ferguson is a postdoctoral researcher at University College Cork (UCC) and part of the EU-funded FreeHydroCells project. His work lies at the intersection of 3D printing, electrochemistry, and sustainable energy technologies. We spoke with him about his journey from undergraduate student to postdoc, the science behind his work, and what lies ahead.

Can you tell us a bit about your academic journey?

Sure! It’s all been at UCC, actually. I started a degree in Biological and Chemical Sciences, convinced I’d pursue biology. After the first year, though, I realised it wasn’t for me – I wasn’t enjoying the biology aspect so much. However, I loved the chemistry modules, so that’s what I decided to pursue for the rest of my degree! My final undergraduate year was during the COVID lockdown, which wasn’t ideal for the full “college life” experience, but perhaps also helped with studying for final exams.

I didn’t do a master’s – I went straight into a PhD after finishing my undergrad. I reached out to several supervisors about postgraduate positions and Professor Colm O’Dwyer responded with an opportunity to pursue a PhD in his Applied Nanoscience Group. I’ve been working with the same group since, now continuing as a postdoc.

What changed for you between undergrad, PhD, and postdoc?

It’s definitely become more personable. The people who were once lecturers, demonstrators, etc are now colleagues and even friends. The environment feels more familiar. Overall, it’s a very positive working environment here in UCC. I’ve very much enjoyed my time working in Ireland, but for the next step I’ll be hoping to continue my career elsewhere in Europe (France, Germany, Belgium, the Netherlands, etc.).

What’s your role in the FreeHydroCells project?

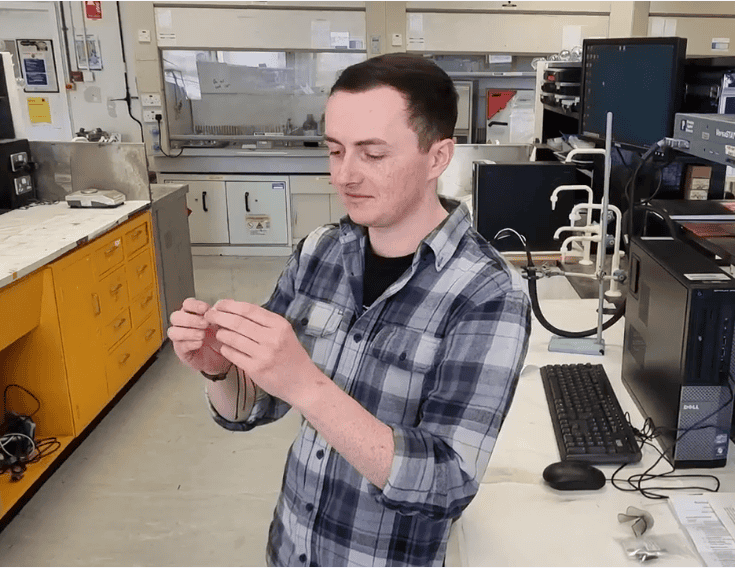

I use SLA 3D printing to create complex, high-surface-area, lattice electrodes. We design several different lattice geometries and coat them in electroactive materials – for now, simple, well-understood materials, like nickel and gold. We then carry out various electrochemical tests on these coated lattices to determine which ones perform the best; overall stability, current responses, volume of hydrogen gas evolved, etc.

Eventually, we’ll collaborate with other FreeHydroCells partners who are developing advanced photocatalytic coating materials. The goal is to combine our best-performing lattices with their advanced materials to contribute to a full water-splitting device that produces hydrogen more efficiently.

Is this work similar to your PhD research?

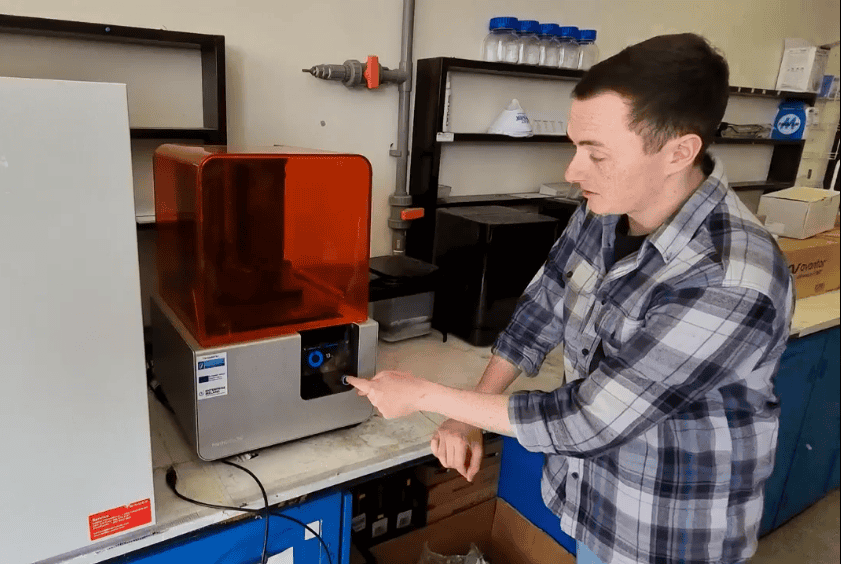

Very similar! During my PhD, I used the same 3D printer and similar electrochemical analyses, but for energy storage – specifically supercapacitors. Supercapacitors are like batteries, but simpler in their chemistry and energy storage mechanism. They discharge their stored energy in a quick, powerful burst, rather than slowly over time. The core techniques for that work were the same, so transitioning to water splitting felt quite seamless.

How do you design and produce these 3D-printed electrodes?

We start with CAD software like FreeCAD to design the lattices. We vary the geometry to create different surface areas and bubble pathways. Once designed, we upload the files to the printer, which does the rest. We’re using an SLA 3D-printer for our work. The raw material consists of a photopolymerisable liquid resin, which is selectively solidified by a laser light layer-by-layer until your printed models are complete.

After printing, we clean the lattices of any residual liquid resin and place them into a UV-light curing machine, which hardens the material. Then we coat them with the electroactive materials that we wish to test. It’s a user-friendly process – thankfully, the printer does all the technical heavy lifting.

How do you decide which geometries to test?

We reused six or seven lattice designs from previous projects in Colm’s group – mostly ones that worked well for batteries or supercapacitors and theoretically would work as water splitting electrodes. We didn’t want to go overly complex; simpler designs are easier to print and fully-coat in electroactive materials, especially when we move onto the more complex multi-layer materials I mentioned before.

Have any particular lattice types stood out?

Yes – one lattice has consistently outperformed the others in nearly every test. It’s also the easiest to print, so we’ll likely move forward with that one for the next phase of collaboration.

How new is the concept of 3D printing electrodes? What was done before?

It’s probably only a decade or so old. Earlier 3D printers weren’t as advanced as the models that we are using for our work, so initial designs for printed lattices were quite basic. Over time, as 3D printing technology improved, so did the complexity that could be achieved for printed electrodes. The best catalyst materials for HER and OER reactions are often incredibly rare, therefore very expensive (like platinum metal). 3D printing allows us to print high-surface-area templates which are coated with thin layers of electroactive material – giving us much larger electroactive surface areas while only using a fraction of the catalytic material.

What drew you to electrochemistry and 3D printing in the first place?

During my undergrad, I was never interested in organic chemistry or pharmaceuticals. Instead, I was fascinated by the physical and inorganic chemistry side of things. When Colm explained his group’s work – 3D printing electrodes for batteries and supercapacitors – it just sounded incredibly cool. I hadn’t used a 3D printer before, and the idea of combining that with energy storage really clicked. He sold it well, and I’m still here!

How has your experience with FreeHydroCells been so far?

Very positive! I’ve been on the project since January, so about six months now. Compared to my PhD, the workload is a bit more relaxed, which is great. The team is lovely and very engaged in their work.

Is this your first time working in a multi-country consortium?

Yes, this is the first time I’ve been part of such an international team. My PhD was quite individual, but my work as a postdoc feels much more collaborative. It’s not just me – there’s a whole team working toward the same goal.

What aspects of collaboration do you enjoy most?

A few things: first, the travel. I love visiting new places, and this project spans Ireland, Italy, France, and Germany – all fantastic countries to explore.

Second, seeing how other teams approach the same challenges. Sometimes they’ll have a better method or insight, and it makes you think, “Why wasn’t I doing it this way all along?”

What do you like doing outside the lab?

I’m a black belt in Taekwondo, which I earned last year – the same year I finished my PhD, so it was a busy one. I also play acoustic guitar, read a lot, and generally enjoy staying active by cycling around the countryside of West Cork where I am living.

Do you see yourself continuing in this field long term?

I’m very open. I’d be happy to continue working in 3D printing and electrochemistry, especially in Europe. However, if another opportunity in physical or materials chemistry comes up where my skills apply, I’d be open to that too.

Do you see yourself staying in academia? Or moving to industry eventually?

For now, I prefer academia. I enjoy the flexibility, autonomy, and less rigid environment. Down the line, if I settle in a specific country and a stable industry opportunity comes up, I’d definitely consider that too.

Any key lessons from your time on the project so far?

Definitely: don’t be afraid to ask for help. My PhD was more independent, but here it’s a team effort. At first, the jargon and project-specific language were a lot to take in, especially since I joined quite late into the project. With that said, everyone’s been really supportive and helped bring me up to speed. That collaborative mindset has been a big takeaway.

Related reading “FreeHydroCells: A Bold New Path for Clean Energy and Climate Action”